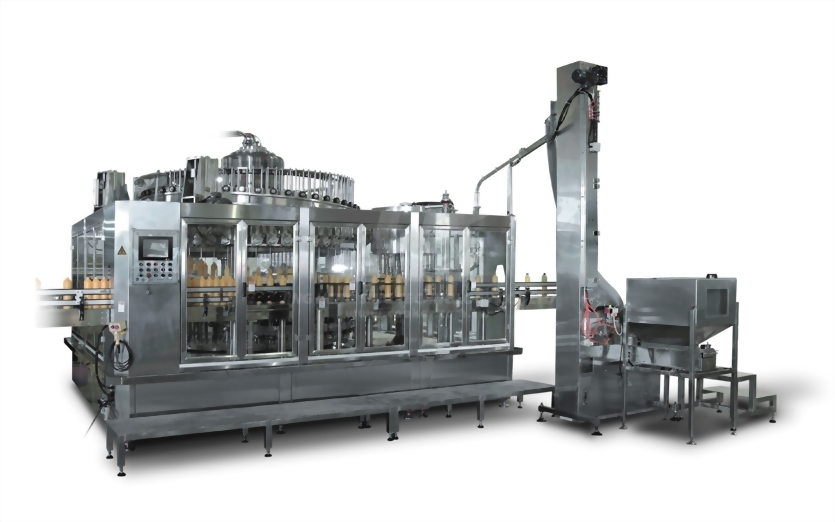

3-1 RINSER-FILLER-CAPPER

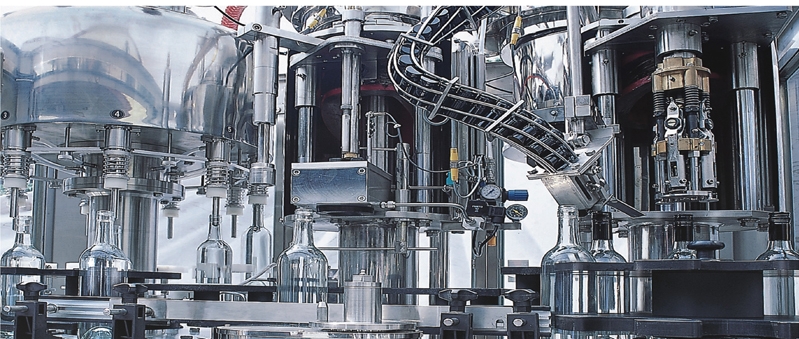

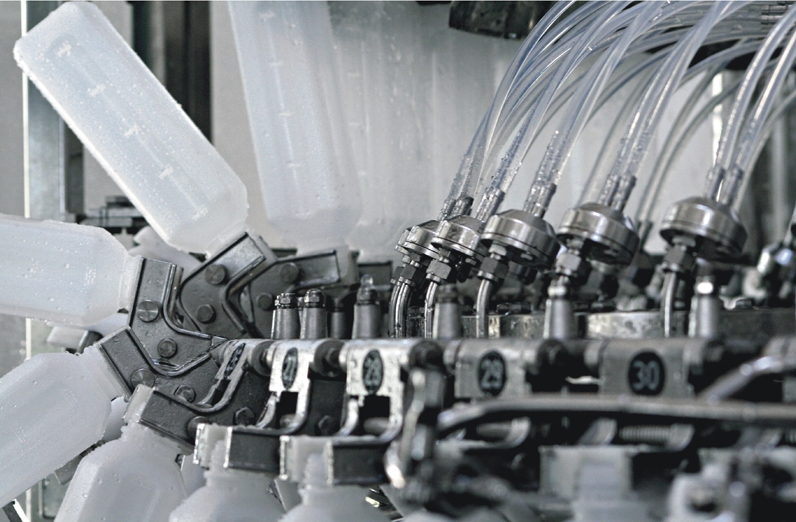

RINSER :

Rinser is suitable for washing glass bottles and plastic bottles of various materials with easy operation. The machine is suitable for different sizes of bottles by changing proper accessories with simple actions, without need of any tools.

FILLER :

Gravity Type Filling -

The gravity filling type and is suitable for filling fresh milk, drinking yogurt, fresh juice (content with fiber) and the temperature sensitivity products. The designs of this filler are two models : normal type and auto. CIP type. There is a safety cover in the machine surrounding to isolate dust and foreign object. The filler can equip with HEPA on the machine top and is suitable for fresh cool storage products.

Convection Type Filling -

This filling principle can prevent product form polluting and increase filling speed. The filler is suitable for Tea Drink, non-granule juice, mineral water and etc. When filling, the product flowing back system can ensure the constant filling temperature. The product liquid will flow back to the recycle tank firstly, via the sanitary pump motion, flow back to the pasteurizing equipment to pasteurize, then flow to the filling bowl. It is not suitable for the temperature sensitivity products.

Piston Type Positioning Filling -

The piston & level positioning filling type and suitable for filling liquid which is high and low viscosity contents with granule such as yogurt, sauce and etc.

Piston Type Volumetric Filling -

The piston type volumetric filling, it is suitable for filling high viscosity sauce, it adopts non-touch filling, the process of piston is able to change to adjust the filling volume. The machine is able to do auto. CIP cleaning.

Carbonated Soft Drink Filling (Equal Pressure) -

The designs of this filler are two models bottle type and can type. The filler is suitable for filling plastic bottle type drinks, glass bottle type drinks or can type drinks such as Soda Water , Champagne , Beer, Carbonated Soft Drink and other carbonated beverage .

High-Vacuum Filling -

High vacuum filling that is suitable for sauces with a higher viscosity, such as soy sauces paste, tomato ketchup, thick chilly sauce and etc.

Flow-meter Filling -

Use flow type meter to control filling product amount. This allows the each product's filling amount accurately and consistently. With non contact filling to further prevent pollution caused by products contact with filling valve.

Weight Filling -

The filling system design is from load cell and control unit to control the switch of filling valve. Filling will automatically deduct the weight of the bottles. When the filling is about to reach the set filling volume, the filling valve port will turn small and filled with small flow rate. This allows filling accuracy more precisely. Also, it uses non-contact filling and is applicable to non-carbonated low viscosity liquid.

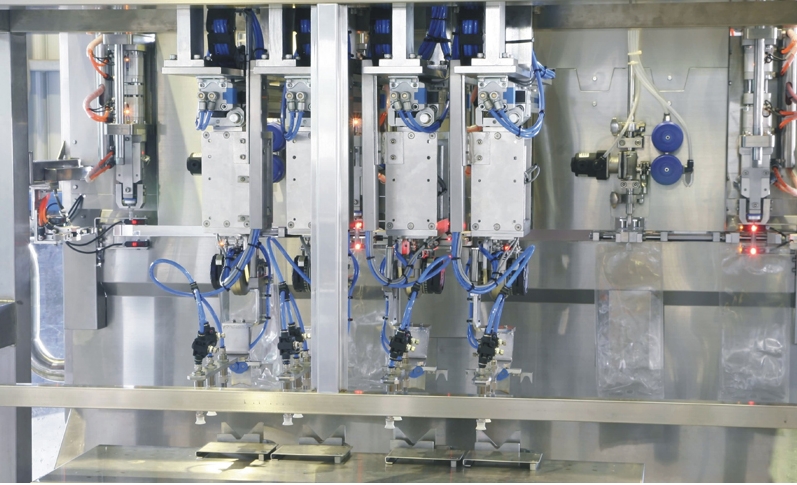

Injection bag filling -

The filling design is suitable for bag filling, and equip with flow transmitter to control filling volume. Operators could input the demand filling volume in the touch screen to control filling volume. All valves and fittings which contact with product are medical grade. The filling equipment is equipped with CIP & SIP cleaning motion and operated friendly.

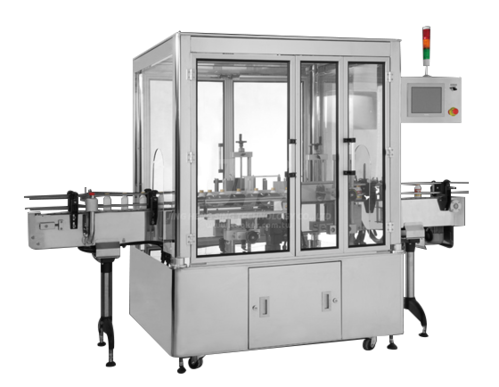

CAPPER :

Capper - Capper is with star wheels to pick up plastic caps. The star wheels respectively used for bottles and plastic caps are operated synchronously so that the plastic caps canbe precisely aligned with and screwed on the bottle mouths in the high-speed production.

Press-On Capper For Aluminum Cap -

Press-on capper can be adjusted respectively in the top pressure and the side pressure to make sure of good quality in rolling aluminum caps. The thread-rolling cutters of the machine hardened and toughened with heat treatment are hard to be worn.

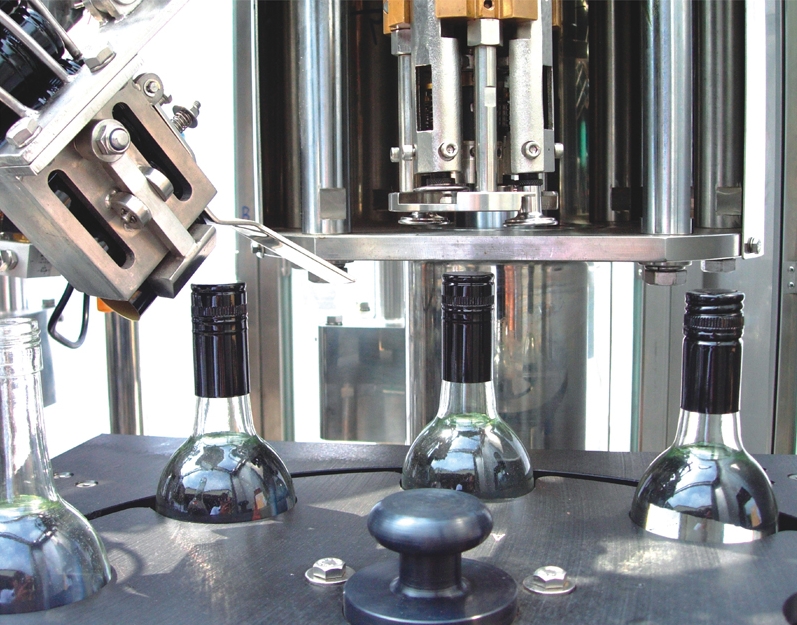

Crown Capper -

Crown cap can be arranged one by one by cap selector, by cap chute, caps will be delivered to star wheel, then capper magnet will catch crown caps to match with bottle opening, after forming, the crown caps will be sealed on the bottle opening.

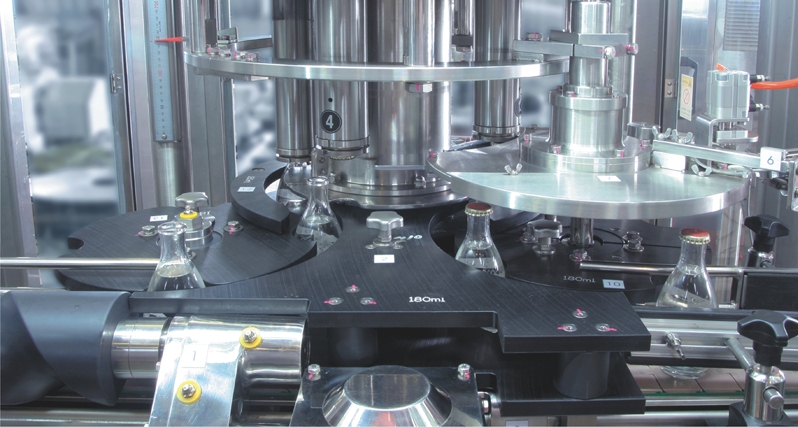

Filler - Corker / Aluminum Capper :

The machine combines with filling, cork inserting and aluminum capping three functions in one machine and could choose to insert cork or seal aluminum cap only. It adopts gravity filling. The filling level depends on the position of air drain hole, and could be controlled by adjusting the height of gaskets.