VEGETABLE CHIPS MAKING MACHINE

- How to make vegetable chips and fruit chips?

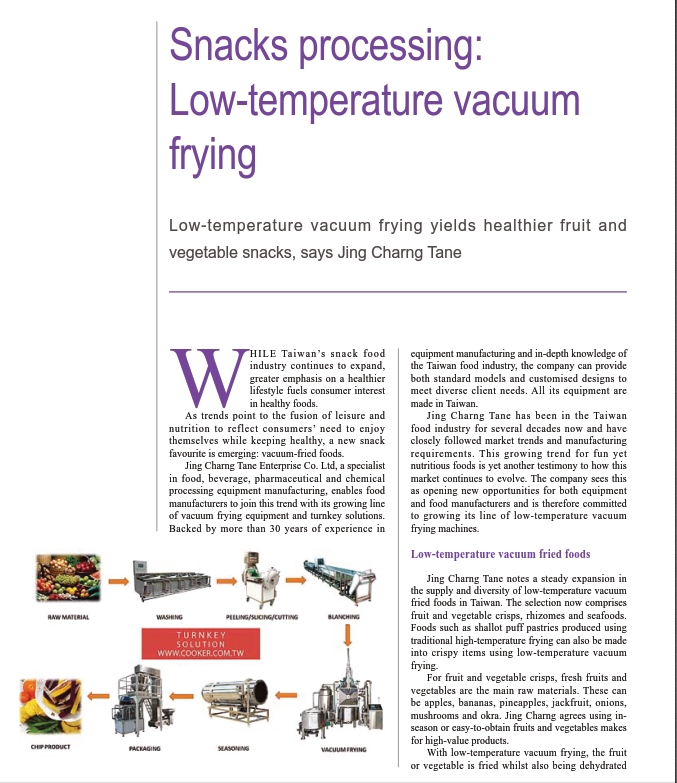

- Vegetable chips and fruit chips producing process is as following:

Raw Material Washing → Peeling / Slicing / Cutting → Blanching → Vacuum Frying → Seasoning → Packaging

- Machinery to make vegetable chips and fruit chips:

.

- Video to show how to produce vegetable chips:

SOURCE: EBC FINANCIAL NEWS

- Video to show our vacuum fry system with industrial scale:

- Video to show our vacuum fry system for large scale production:

Vacuum Frying Machinery Supplied By Us. This is Medium Scale System.

VACUUM FRIED VEGETABLES, FRUITS AND SEAFOOD -

Vacuum frying is to fry the raw materials in a closed and decompressed environment to make the raw materials dehydrate. It can retain the original color of the raw materials and produce a special mouthfeel.

The traditional high-temperature frying is between 160 and 185 ° C. If starch-based foods (generally above 120 ° C) are fried or baked at high temperature, such as bread, sweet potato, taro, potato, etc., a large amount of "Acrylamide" will be produced, which is a kind of chemical that has been shown to have adverse effects on humans in animal experiments.

Frying is performed in vacuum condition, and the frying temperature can be greatly reduced to 90 to 110 ° C. In the state of vacuum, the boiling point of water is reduced, and then the oil is used as a heat transfer medium to evaporate the water content of the raw material to achieve the purpose of frying and dehydration, and it can make the food's tissue porosity appear crispy.

The vacuum frying temperature is low, and the near-vacuum, oxygen-free state in the fryer can avoid rancidity, browning, and oxidative deterioration of the oil and products, so that the fried food can maintain the flavor and color of the raw material itself, and greatly reduce the degradation caused by fat of harmful substances.

Currently Taiwan's vacuum low temperature fried food market can be divided into four types.

A. Fruit and vegetable crisps: Fresh fruits and vegetables are the main raw materials, such as apples, bananas, pineapples, jackfruit, onions, mushrooms, okra, etc. You need to choose raw materials that are easy to obtain to make it high valued products.

B. Rhizomes: Rhizome crops are the main raw materials, such as potatoes, sweet potatoes, and taro.

C. Seafood: all kinds of seafood are the main ingredients, such as shrimp, squid, crab, small fish etc. It can preserve the freshest and sweetest natural seafood.

D. Traditional high-temperature fried products such as red shallot oil, shallot puff pastry, garlic, etc.: The vacuum low-temperature deep-frying dehydration process is used to replace the traditional high-temperature fried products. The expected hardness and color of the ingredients can be obtained. Also, the fried oil is not easy to deteriorate and can be reused because frying temperature is lower than 120 degrees.

MACHINERY -

We supply very reliable vacuum fried chips making system. Good quality. Made in Taiwan.

**Article Written By Jing Heng Sing Technology**